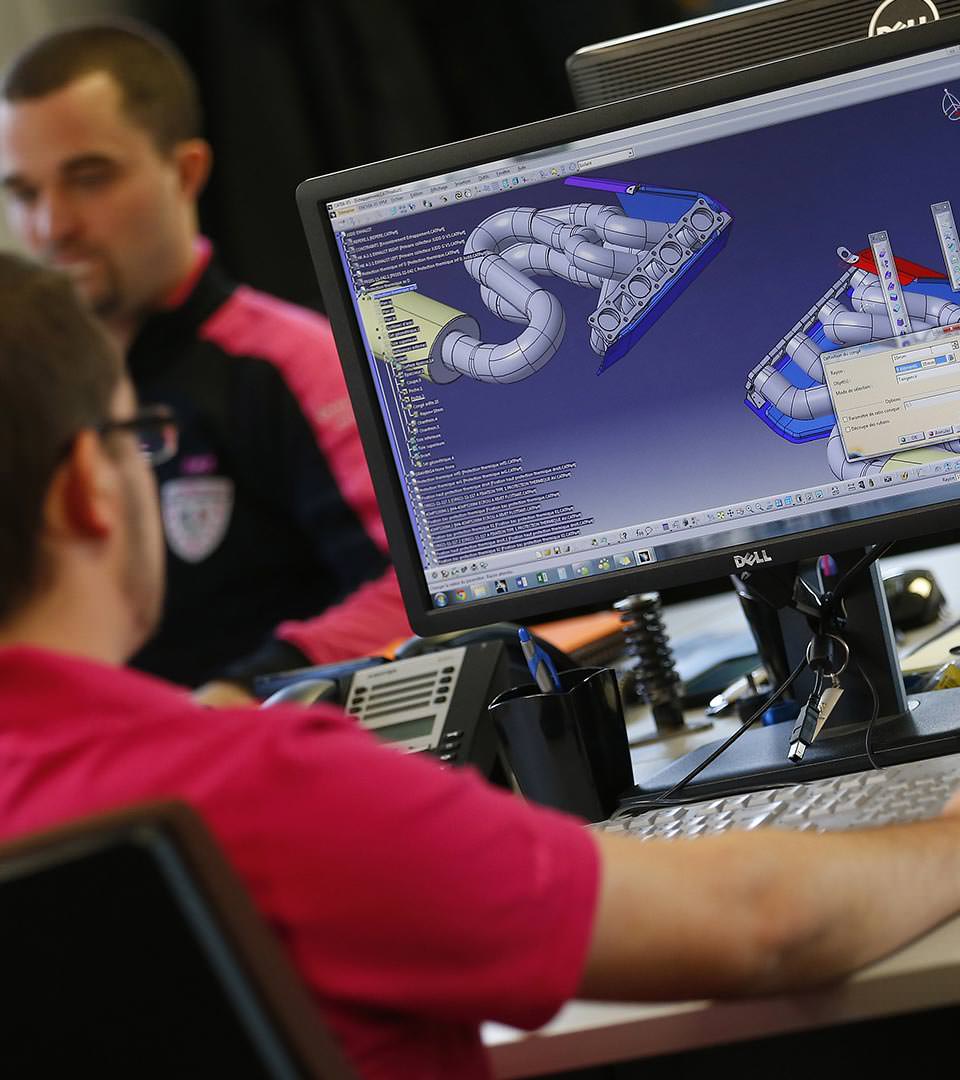

Design

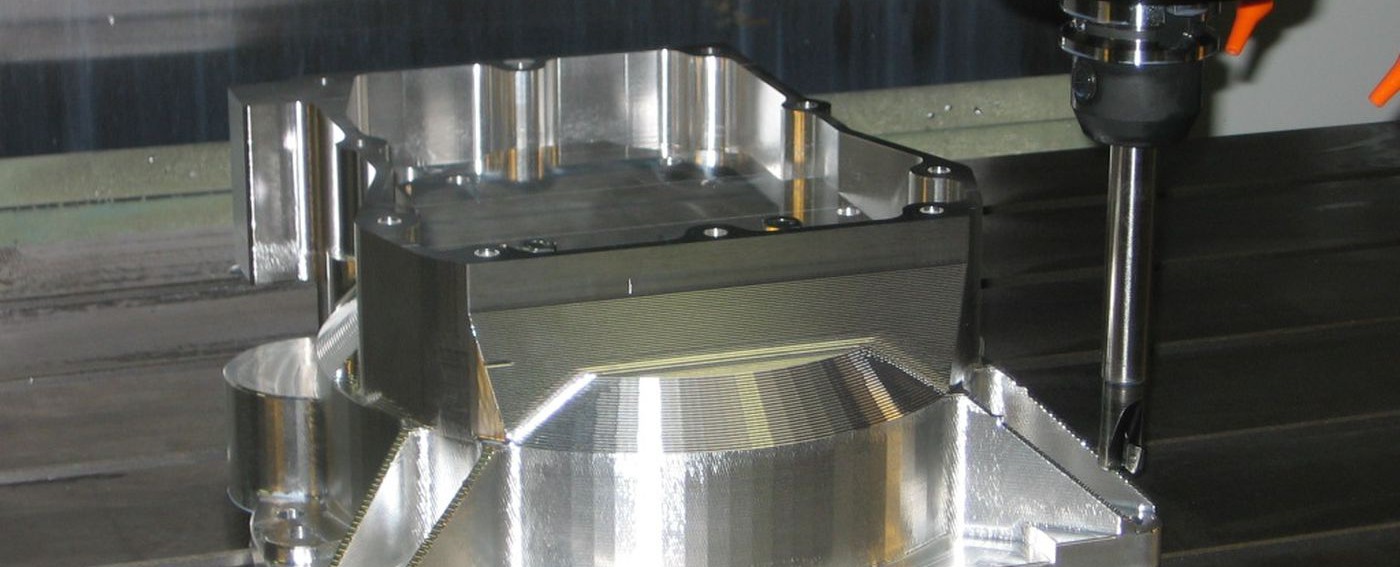

Ligier Automotive's various design offices master all the skills required to design a race car chassis, integrate or develop a powertrain, and embed advanced electronic systems.

While respecting the technical and budgetary constraints related to design, production, and race operations, Ligier Automotive always aims to optimize performance, reliability, and safety.