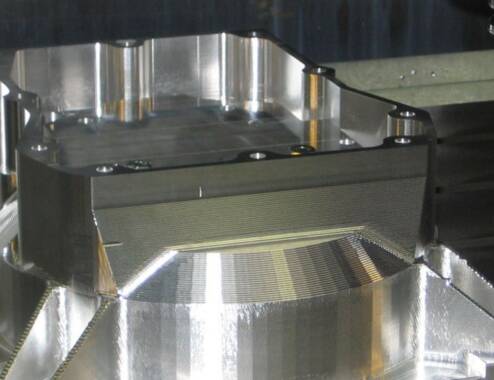

High-Precision CNC Machining for Prototypes and Small Series

At Ligier Automotive, our CNC machining workshop is equipped to meet the highest demands in precision, geometric complexity, and repeatability. We manufacture custom technical parts, from one-offs to small production runs, for both motorsport and specialized industrial applications.