High-Precision Welding Techniques

We employ TIG, MIG, ARC, and brazing techniques, adapted to the exacting requirements of motorsport.

Our teams are experienced in welding a wide range of materials including standard steels, heat-treated steels, annealed steels, aluminum, and stainless steel.

Each part is inspected using a 3D coordinate measuring machine (CMM) to ensure dimensional accuracy.

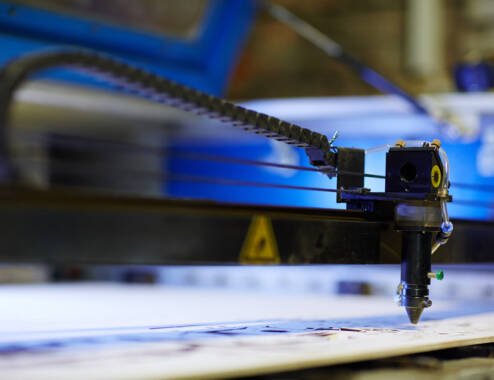

A laser marking system guarantees full traceability—essential for the quality and reliability of structural components.

All production is managed through Manufacturing Resource Planning (MRP) software, ensuring process control, delivery tracking, and workflow optimization.

Ligier Advanced Technologies is ISO 9001 certified, confirming that our processes are thoroughly documented, consistently monitored, and continuously improved. This certification reflects our commitment to customer satisfaction, product reliability, and risk management at every stage of development and production.